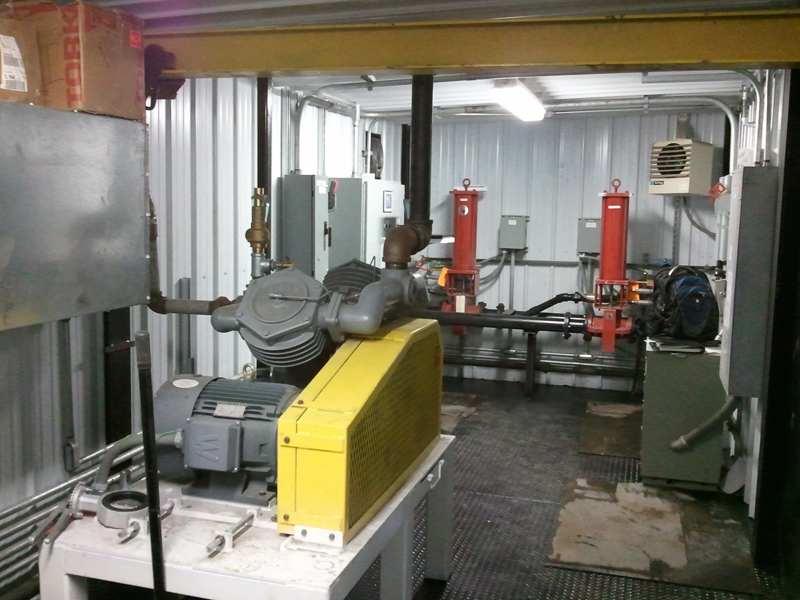

The objective was to create a rock dust tank system at a mine site in order to facilitate receiving material from a transport truck, storage of the rock dust on the surface, and delivery of material underground to a waiting rock dusting pod.

Because proper applications of rock dust can prevent the propagation of coal dust explosions, Mine Safety and Health Administration regulations requires that all areas of a coal mine that can be safely traveled must be kept adequately rock dusted to within 40 feet of all working faces. Due to the large quantity of rock dust required on a daily basis for usage in the mine, Mon Valley Integration was tasked by our customer to create a system that would not only store a large quantity of dust, but would able to deliver it underground on demand in a safe and efficient manner.

This system will allow truck drivers to unload their payload into the surface rock dust tanks safely by providing status lights and selector switches to disable the system while material is being transferred.

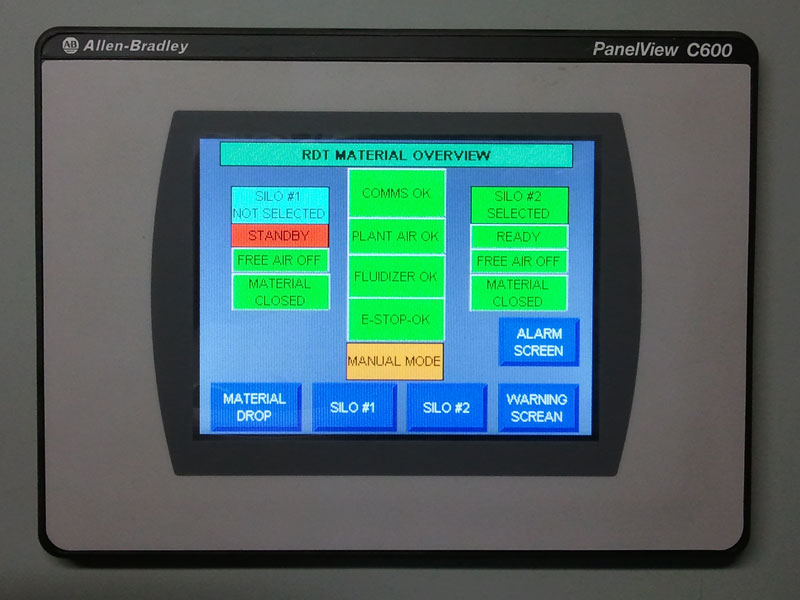

This system is self-monitoring, with Programmable Logic Controller (PLC) monitoring for all aspects of the process: delivery, storage, and transfer. PLC systems are located on the surface and underground to enable remote monitoring, control, and troubleshooting.

By collaborating with the customer, the objective was achieved. With a successful installation, the Rock Dust Control System became a valuable addition to the client’s facility.